Exhaust manifolds in tuning

An exhaust manifold also called a turbo manifold or a header (in its optimized form) is the first component of the exhaust system, right on the cylinder head.

The manifold only tends to get a mention if it fails and causes problems. However, it’s really important in tuning and enhancing vehicle performance when it’s optimized along with the rest of the exhaust system. So let’s put it under the microscope and explain the technology behind it, what it does, and so on.

What is an exhaust manifold?

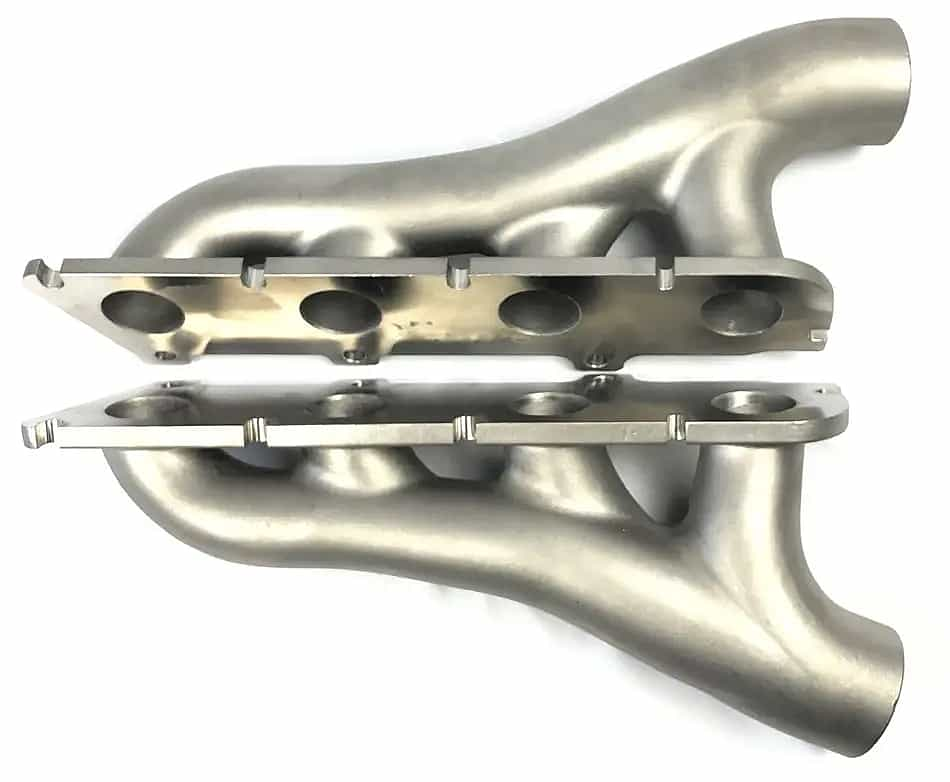

An exhaust manifold is part of the exhaust system and sits right on top of the cylinder head. It takes exhaust gases collected from the individual cylinders to the turbocharger or to a collector pipe. As such, it’s one of the most stressed components in your car. The forces at work on the manifold are immense, especially given its exposure to extreme heat from the exhaust gases (which can reach over 1,000°C). Consequently, materials play a major role: many turbo manifolds are made from cast iron or stainless steel and often feature special alloys. Particularly in motorsport, where high performance is another factor that pushes up the temperature, the materials used have to be correspondingly tough. At the same time, every gram counts on the racetrack, so weight-saving stainless steel is becoming more and more popular.

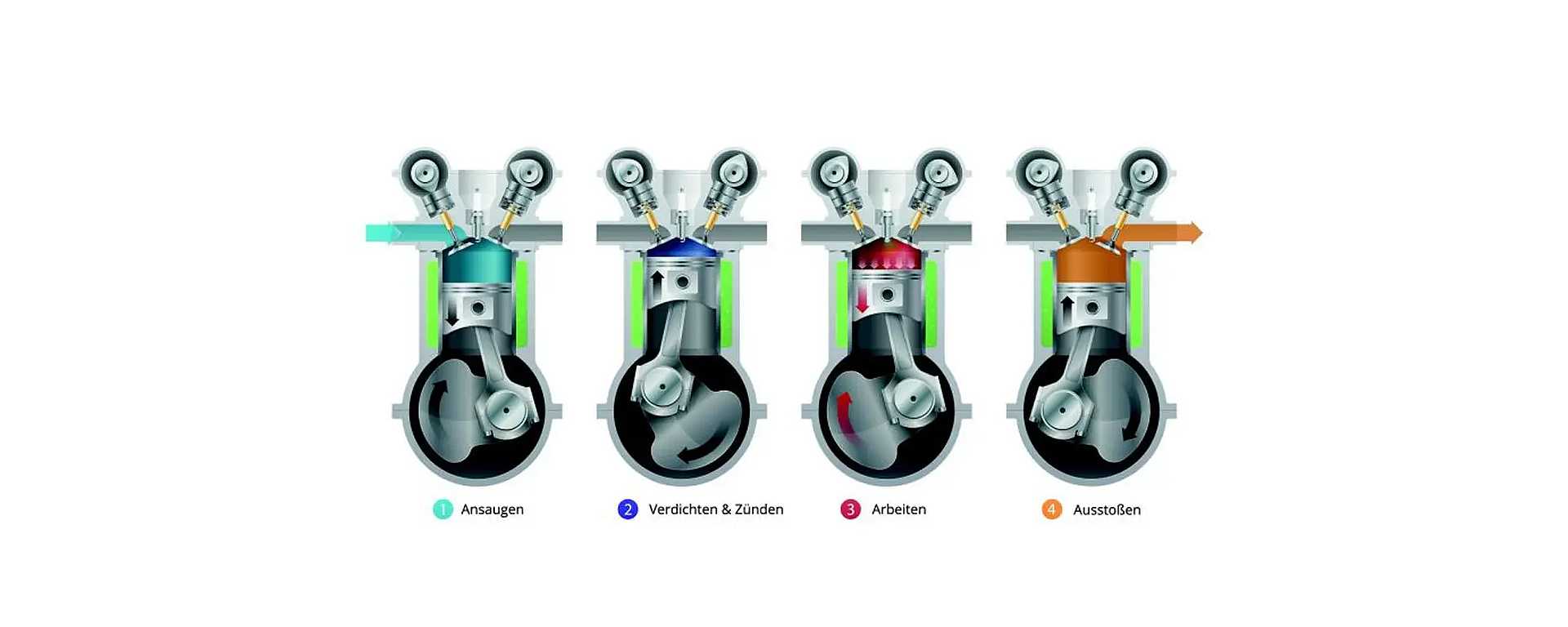

How does the exhaust manifold work?

The exhaust manifold is designed to take away the exhaust gases from the individual cylinders. And that’s exactly why it’s curved. The hot exhaust gases from the cylinders flow through the turbo manifold and onwards to the turbocharger or a pipe, where they’re collected. At this point, they’re cleaned and taken to the exhaust system. Exhaust gases from the engine usually enter the manifold horizontally and are ducted downwards from there.

In tuning, the goal is to streamline the manifold as much as possible so that it discharges the exhaust gases quickly and efficiently, preventing them from flowing back into the cylinders. Manifold designs differ according to the ignition sequence because the exhaust gases flow into the manifold so fast that they create a vacuum that sucks them in and almost out of the engine. This applies particularly to sophisticated header designs.

Pipe length and diameter, pipe joints, and welds are key criteria in high-performance exhaust manifolds. These factors can have a big influence on the gas flow. For example, weld roots inside the pipes can cause turbulence. So the manifold interior has to be as smooth as possible to guarantee the optimum flow ratio.

Pulse charging manifolds and constant pressure manifolds

There are two types of manifold: constant pressure, and pulse charging. Constant pressure manifolds are used in series production, but also in tuning. This is mainly because they’re smaller. They’re usually made of cast iron but are sometimes welded. This is because the channels should be as short as possible before they go to the turbocharger. Exhaust gas accumulates in front of the turbo; this is what drives the turbine. With pulse charging, the ignition sequence is taken into account. The pipes are twisted and welded, and their length as equal as possible. The pulse charging manifold drives the turbine via the exhaust gas accumulation and also via the pulse energy that the exhaust gases produce at the exhaust valves.

Immediate delivery!

Performance manifolds in tuning

In tuning especially, it’s important to use performance manifolds, particularly in terms of optimized exhaust gas routing and heat-resistant materials. The ideal scenario is for the manifold to be plugged into the intake plenum. This prevents heat strain and the pipes can be designed with very thin walls without fear of rupture. If you’re using an upgrade pulse charging manifold you can also install a very large turbocharger. This means you can also directly influence torque and response. An upgrade manifold will give you a buzz: it boosts acceleration and gas flow rate. On request, you can get our patented plasma ceramic coating, which makes your manifold heat-resistant to 900°C (and what’s more, it looks incredible). Our manifolds often also have a port for an external wastegate.

Manifolds and the environment

Manifolds are not just good for performance: they’re good for the environment, too. Generally speaking, you want to keep most parts cool. But not with the manifold. It has to be designed to minimize the amount of exhaust gas heat it can absorb and release. Because you need your catalytic converter to reach operating temperature as quickly as possible so that it can keep emissions correspondingly low. That’s why modern exhaust manifolds often have an air gap between the actual (very thin-walled) pipe and its casing. The pipes themselves have a low heat capacity and the air helps to insulate them. This means the hot gases can heat up the cat unhindered.

Immediate delivery!

Immediate delivery!

Faulty exhaust manifolds

The most common faults on exhaust manifolds are caused by cracks and ruptures, usually due to high thermal stress followed by cooling. Engine vibrations can also put your manifold out of action. If it’s faulty, you’ll generally notice not just loud engine noise but also declining performance and higher fuel consumption. And if you start to smell exhaust gas in your car interior, that’s a sure sign.

Questions about manifolds?

We’re happy to help. Send us a chat message or check out our FAQ.