Kolbenringe montieren

Kaufst du fertige Serienkolben von VW oder Audi, sind die Kolbenringe bereits montiert. Das ist nicht der Fall, wenn du dir den Motor selber baust oder dir von uns einen Rennmotor bauen lässt.

Dann musst du die Kolbenringe noch auf den Kolben aufsetzen. Hier erfährst du, wie du Kolben vorbereitest, die Kolbenringe montierst und die Kolben anschließend mit den Pleueln verbindest.

Die Funktion – Wozu sind Kolbenringe da?

Der Kolbenring dichtet unter anderem den Kolben ab. Zusätzlich sorgt er dafür, dass das Schmieröl gut verteilt wird, und er leitet die Hitze aus dem Kolben an die gekühlte Zylinderwand ab. Der Kolbenring ist nicht rund und geschlossen, er verfügt über eine Öffnung, die Ringstoß genannt wird. Erst beim Einbau wird der Ring in einen kreisrunden Zustand gebracht.

Normalerweise werden drei Kolbenringe pro Zylinder mit unterschiedlicher Funktion und aus unterschiedlichen Materialien eingesetzt:

- Der obere Ring ist der Kompressionsring. Er ist für das Abdichten und Ableiten der Hitze zuständig.

- Der mittlere Ring dichtet den Brennraum gegen Verbrennungsgase ab. Er übernimmt auch die Versorgung des Ölhaushaltes an der Bohrung.

- Der untere Ring ist der Ölabstreifring (besteht aus drei Teilen). Er dosiert die Menge des Schmieröls an der Zylinderwand, in dem er das Öl abstreift.

Was ist das Stoßspiel der Kolbenringe?

Kolbenringe verfügen über eine Öffnung. Der Abstand zwischen den Kolbenringenden im eingebauten Zustand ist das Stoßspiel, auch Ringspiel genannt. Dieses wird im eingebauten Zustand gemessen, während der Kolbenring senkrecht zur Zylinderwand steht. Um den Kolbenring einzusetzen, kannst du spezielle Tools, den Kolben selbst oder die eigenen Hände benutzen. Wenn wir von der Montage der Kolbenringe reden, meinen wir auch das Einstellen des Stoßspiels. Wie du das Ringspiel richtig einstellst, siehst du weiter unten.

Wieso brauchst du neue Kolben und Kolbenringe beim Tuning?

Wenn du neue Kolben für deinen Serienmotor brauchst, kannst du auch Serienkolben verbauen. Diese sind fertig montiert, die Kolbenringe sitzen schon an Ort und Stelle. Beim Tuning sieht die Sache anders aus. Hier wirken so hohe Kräfte, dass die Serienkolben der Belastung durch den höheren Ladedruck etc. nicht standhalten können. Auch die Maße der Bohrung stimmen nicht mehr, wenn wir den Motor mit der nächst höheren Bohrung bauen. Die Verdichtung ist ebenfalls ein Grund, weshalb Serienkolben beim Tuning nicht funktionieren. Hier gehen wir deutlich mit der Verdichtung runter, da wir für mehr Leistung auch einen höheren Ladedruck benötigen. Ein Indikator für eine geringere Verdichtung ist die Größe der Mulde im Kolbenboden: Je größer die Mulde, desto geringer die Verdichtung.

Kolbenringe montieren: So stellst du das Ringspiel korrekt ein

Das Ringspiel deiner Kolbenringe musst du nicht nur überprüfen, sondern auchanpassen. Das machst du individuell für jeden Zylinder. Denk daran, dir die Messwerte in deinem Protokoll zu notieren. Dort kannst du unter anderem die Bohrung und das Ringspiel eintragen. So hast du die Werte immer parat, wenn du wieder etwas verändern willst. Bei deinen Kolben ist immer ein Installationshinweis dabei, die „ring installation guidelines“. Folge diesen Schritten für das Einstellen des Ringspiels:

- Sortiere die Kolben und die dazugehörigen Kolbenringe in der richtigen Reihenfolge. So entstehen am wenigsten Fehler.

- Beachte die Einbaurichtung: Auf der Einlassseite sind die Taschen im Kolben tiefer.

- Der erste Kolbenring glänzt, der zweite ist dunkler und matt. Die Markierung auf dem Ring zeigt nach oben.

- Anschließend drückst du den Ring, den du bearbeiten willst, in den Zylinder. Wir haben dafür ein selbstgebautes Werkzeug aus Kunststoff, du kannst auch den Kolben nehmen. Achte darauf, dass der Kolbenring wirklich parallel zur Öffnung sitzt.

- Als nächstes brauchst du Fühlerlehren (Abstandslehren), um das Ringspiel messen zu können. Welches Ringspiel du benötigst, ist abhängig von deinem Motor, deinen Anforderungen etc.

- Passt die Fühlerlehre nicht in den Spalt, musst du den Kolbenring abschleifen. Bearbeite nur eine Seite, um ein optimales Ergebnis zu erhalten. Taste dich langsam ran und schleife nicht direkt zu viel ab.

- Entferne den Dreck vom Kolbenring und prüfe, ob die Enden gerade sind.

- Prüfe noch einmal mit der Fühlerlehre nach und passe den Kolbenring so lange an, bis du den gewünschten Wert erreicht hast.

- Entgrate anschließend alle Seiten, um keine Riefen in den Zylinder zu ziehen.

- Zur Montage auf dem Kolben, fixierst du ihn zuerst.

- Anschließend prüfst du, ob sich der Kolbenring im Kolben drehen lässt oder ob er hakt. Sollte das der Fall sein, muss er noch einmal entgratet werden.

- Ist alles prima, drückst du den Ring von den Enden ausgehend auseinander, um ihn über den Kolben stülpen zu können (ohne ihn zu zerkratzen).

- Prüfe noch einmal, wie gut er sich drehen lässt.

- Hast du alle Ringe eingesetzt, drehe sie so, dass die Kanten nicht übereinanderliegen (wie ein Mercedes-Stern).

- Ist der Kolben fertig, kannst du ihn montieren. Wir nutzen dafür eine Teflon-Büchse. Ein Spannband kannst du auch nehmen, wir empfehlen aber den Trichter.

- Versorge die Büchse, den Kolben, die Kolbenringe und die Pleuellager mit viel Öl.

- Dann platzierst du mit Fingerspitzengefühl die Büchse über dem Kolben, um die Ringe vorzuspannen.

- Ist der Zylinder geölt, kannst du die Kolben jetzt in Einbaurichtung einsetzen. Prüf noch einmal, ob alles korrekt ausgerichtet ist. Dabei muss die Büchse auf dem Block aufliegen. Zum Schluss drückst du den Kolben vorsichtig in den Zylinder.

Brauchst du Unterstützung?

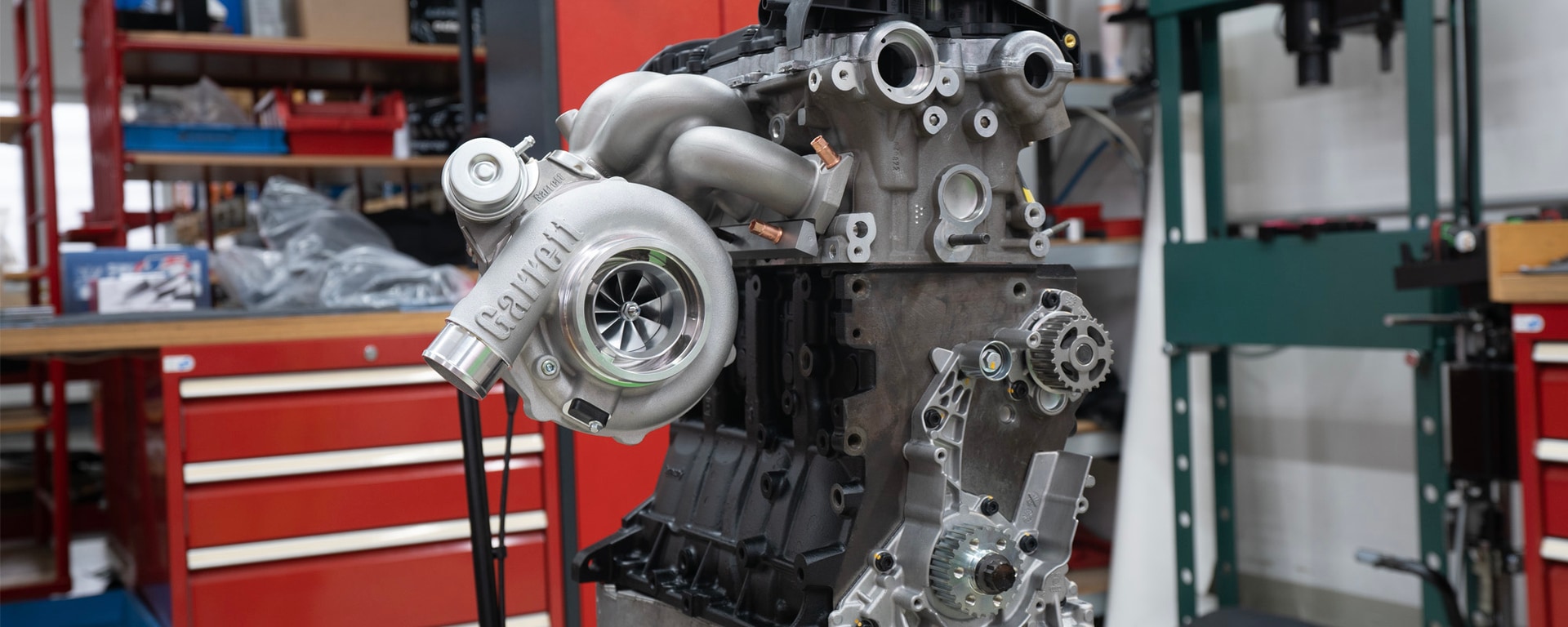

Wir helfen dir bei der Berechnung des Ringspiels und übernehmen den kompletten Aufbau deines Rennmotors. Ruf uns einfach an oder schreib uns.